Bully

Second mate

Posts: 131

|

Post by Bully on Apr 12, 2013 19:59:00 GMT

After purchasing my Wilson in Aug last year, loads of things have gone wrong since.... First trip out to the Solent the engine went, joined Sea Start to tow back to Southampton. Checked the engine over all compressions low, used a bore scope, totally shot on all the cylinders. My fault I should of checked the compressions when purchased!!!! Brought new engine fitted bingo, ran like a dream, went out fishing two weeks ago the deck started to bounce... New deck and other things being fitted, will keep you updated on the progress Boat after last fishing trip, 31/03/13   DAY 1 - 11/04/13 Boat picked up today, Let the work begin. Flyscreen off to get it into the workshop.  Engine bolts removed but the sikaflex was still holding it in place, needed to wedge the engine out, then cut using a fillet knife.  Looks Like a nice deck until you look closer....  The glass just peeled off, not even stuck to the ply.  Foot straight through deck once glass removed   So on day one all the kit removed, flyscreen and engine off, deck started to be ripped up |

|

Bully

Second mate

Posts: 131

|

Post by Bully on Apr 12, 2013 19:59:55 GMT

DAY 2 12/04/13 Removed the bulkhead  Finished off removing the deck  Removing the ribs  It just goes to show, when buying a boat take a person that knows about fibre glassing as all that was done here was to glass over the ribs and not seal them in, All ribs where like sawdust, the deck looked great when I brought it, was told it's just been replaced, all that was done was glassing over the top of sh*t   Already for sanding & grinding down  |

|

bleth

crew member

Posts: 84

|

Post by bleth on Apr 13, 2013 6:41:34 GMT

you must be gutted to have that lot to deal with .but no point in labouring that one

speaking as some-one in the timber industry can i make a few comments on the ply floor

i find it shocking that wilsons fitted such a rubbish ply in the first place but when you replace it you need to use 18mm marine.

tou also need to seal it thoroughly......paint it with PVA watered down about 1/3 rd water 2/3 rds PVA. at least 3 coats and more on the edges

additionally i suggest you avoid the temptation to to re-glass it

or it will only de-laminate in a couple of years

give it a good dose of quality floor paint and drill a 18mm hole between each section of ribs

you can plug these if you like but pull the plugs on a regular basis to get the underfloor moisture content down

if you do this your floor should last at least 10 years & probably a lot more

message me when you are ready to buy the ply & i,ll tell you where to go & get you a sensible price Dave

|

|

Bully

Second mate

Posts: 131

|

Post by Bully on Apr 13, 2013 7:13:03 GMT

Yes mate was well gutted at the time, but once it's all done it will look like a new boat.

I have the ply already 18mm marine, when glassing in the floor the sheets they will be drilled with a 6mm drill holes in places not all the way through, this will then allow the resin/glass to bond to the ply, the ply will be covered on both sides with glass, this will then stop the condensation seeping into the ply from the underside

|

|

Bully

Second mate

Posts: 131

|

Post by Bully on Apr 13, 2013 17:07:22 GMT

DAY 3 - 13/04/13 - Grinding & Sanding All grinded & sanded down, just the sides to do then the good work starts :-)   |

|

Bully

Second mate

Posts: 131

|

Post by Bully on Apr 15, 2013 16:39:51 GMT

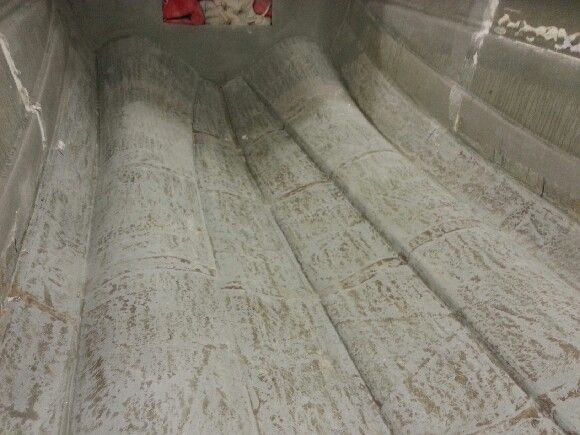

DAY 4 - 15/04/13 Covered the deck with a sheet of mat, with grey pigment   Ribs all cut out and stuck into position with bonding paste   Tomorrow the ribs will all be glassed in. |

|

Bully

Second mate

Posts: 131

|

Post by Bully on Apr 16, 2013 16:15:56 GMT

DAY 5 - 16/04/13 All ribs are glassed in place, a glass sump made instead of making one out of ply. the sump has got a 2" flange all round to allow the new deck to be bonded on top. The bottom will be flowcoated out tomorrow ready for the deck to go down Thursday.    |

|

|

|

Post by backdraft on Apr 16, 2013 18:34:35 GMT

that garrys the kiddie isnt he.

|

|

Bully

Second mate

Posts: 131

|

Post by Bully on Apr 17, 2013 14:28:13 GMT

He sure is, knows what he's doing

|

|

|

|

|

|

Post by skyetoyman on Apr 17, 2013 18:25:01 GMT

1st class work. You'll finish up with a boat that was better than it was when it was first put together.

I had a mate who made his own boat using a mould but he doubled up on fibreglass and made the extra weight made it too low in the water. He could put his thumb on the gunnel and waggle most of his fingers in the water.

|

|

Bully

Second mate

Posts: 131

|

Post by Bully on Apr 17, 2013 18:33:21 GMT

Yeah it will be better than first built, lol did he catch anything when out in it?

|

|

|

|

Post by skyetoyman on Apr 17, 2013 22:03:28 GMT

We were both out in Luce Bay. Me in my 14ft Crescent (a good 2ft freeboard) Him in his heavy 16ft with a cuddy and a small wave washed his sandwich off the transom seat he was sitting on. Having said that we all hammered tope , dogfish and place that week.

Registered for 4 people , I picked up 2 fishermen and a dog plus gear from their disabled boat and ferried them 200 yds to the beach - I already had a boat with 3 people in it.

Now that put it low in the water.

|

|

|

|

Post by zebedee111 on Apr 18, 2013 5:18:56 GMT

No, see my daughter just told me for an effective ball pit that you are going to need more than 400 balls to fill that up!  lovely work on the supports and glass'ing! Tight lines John |

|

Bully

Second mate

Posts: 131

|

Post by Bully on Apr 18, 2013 17:18:03 GMT

put another 400 balls in this morning so there are now 1900 play pit balls under the deck. all the deck has been cut out and dry fitted. the underside has now had a layer of mat on to protect from and water so shouldn't rot out. the deck will be bonded and screwed down in the morning and should be glassed up in the afternoon.      |

|